Motherboard CPU Desoldering Heating Station

1.Motherboard CPU Desoldering Heating Station

2.Brand: Dinghua

3.Model: DH-A2

4. Level of automation: semi-automatic

Beschrijving

Automatic Motherboard CPU Desoldering Heating Station

Automatic soldering and desoldering, with hor-air and large IR preheating area,

used for after-sales service, repairing shop and factory production-line rework etc.

Model: DH-A2

1.Application Of Automatic Optical Alignment Motherboard CPU Desoldering

Heating Station

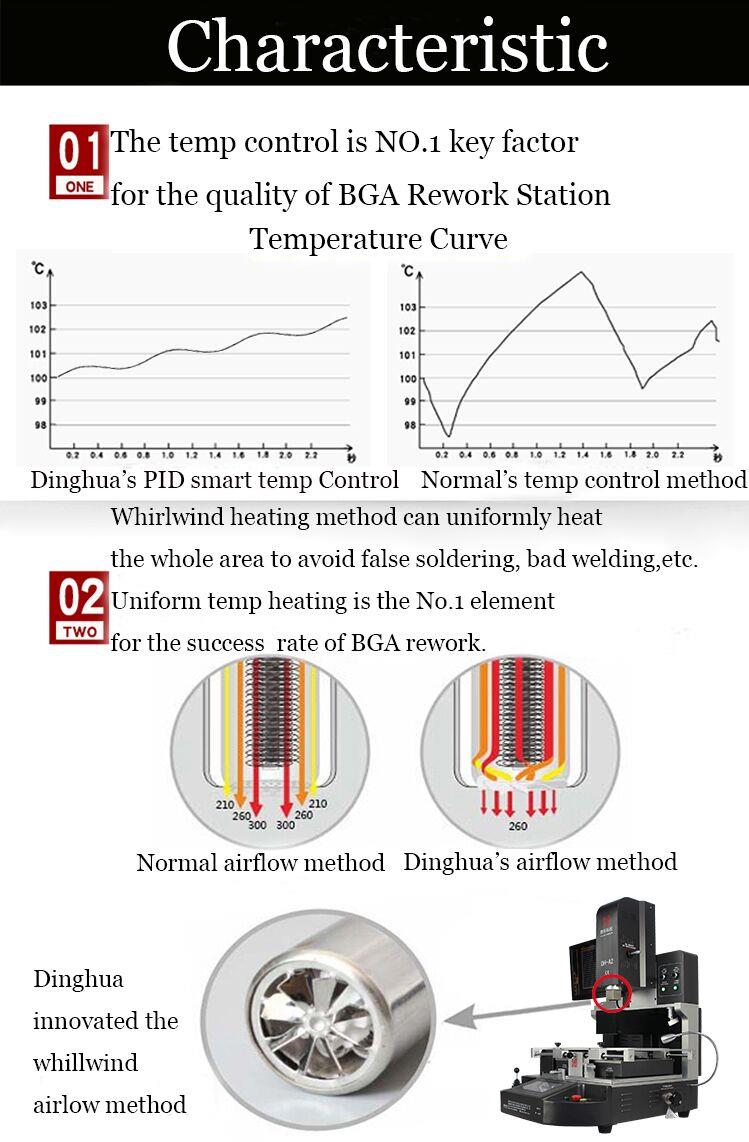

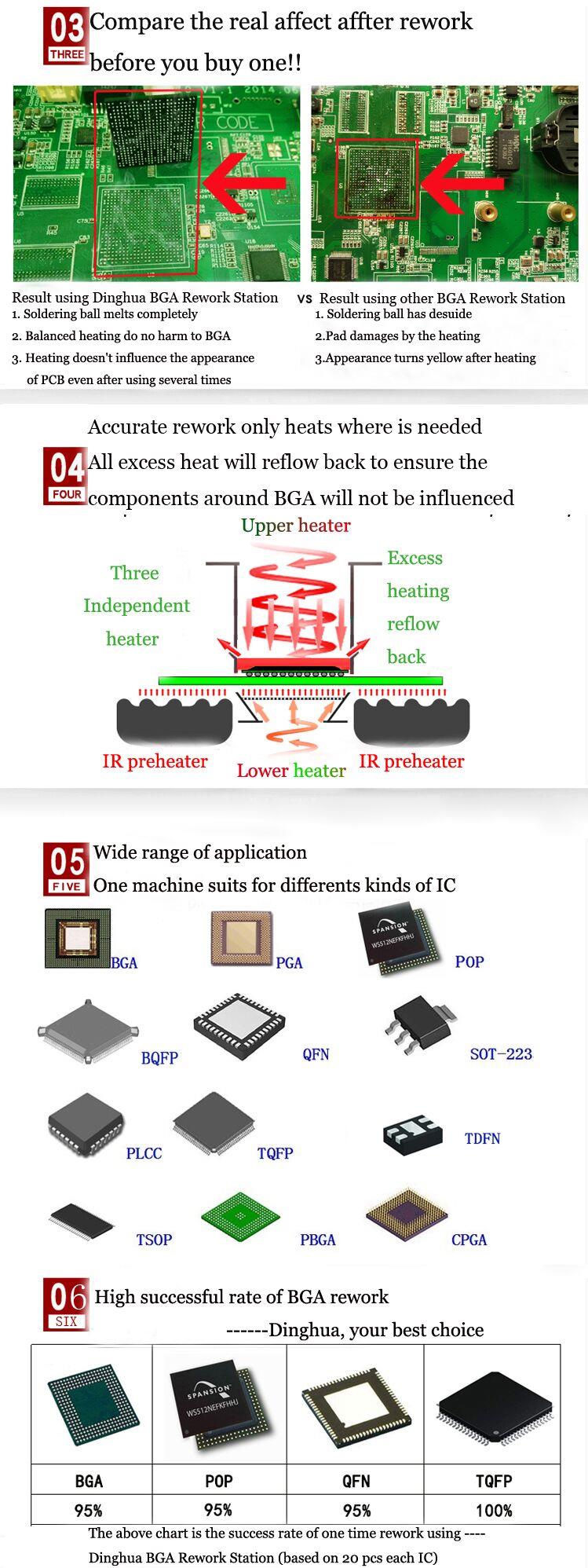

Solder, reball, desoldering different kind of chips: BGA,PGA,POP,BQFP,QFN,SOT223,PLCC,TQFP,TDFN,TSOP, PBGA,CPGA,LED chip.

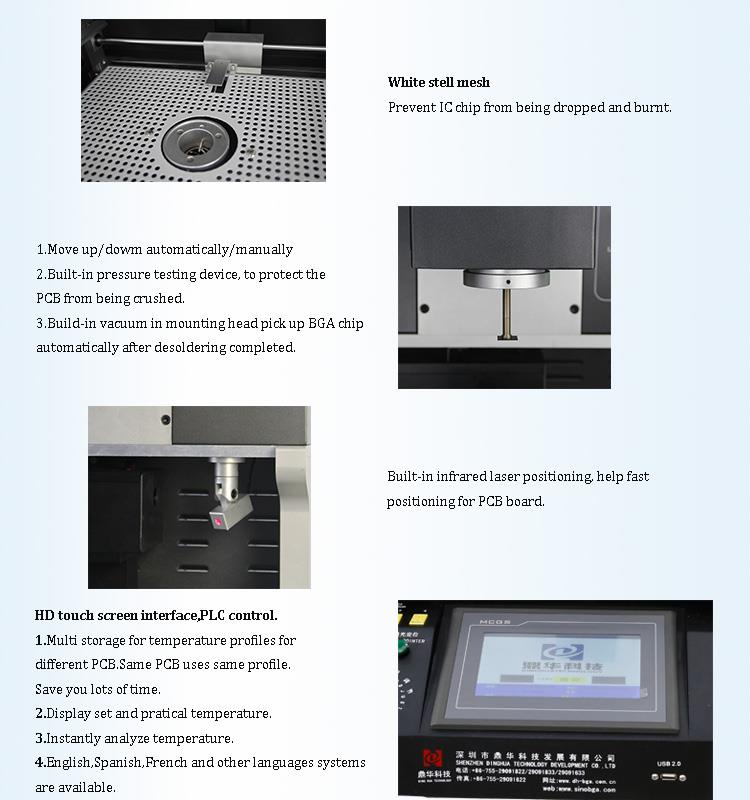

2.Advantage of Automated Optics Motherboard CPU Desoldering Heating Station

3.Technical data of laser positioning Automatic Motherboard CPU

Desoldering Heating Station

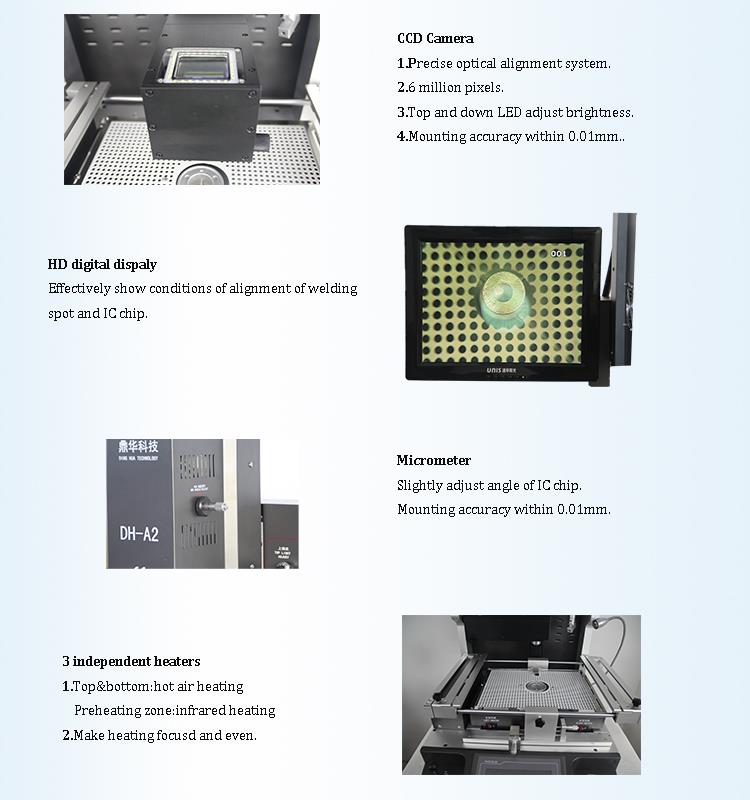

4.Structures of Infrared CCD Camera Motherboard CPU Desoldering

Heating Station.

5.Why Hot air Motherboard CPU Desoldering Heating Station is your best choice?

6.Certificate of CCD lens Motherboard CPU Desoldering Heating Station

UL, E-MARK, CCC, FCC, CE ROHS certificates. Meanwhile, to improve and perfect the quality system, Dinghua has passed

ISO, GMP, FCCA, C-TPAT on-site audit certification.

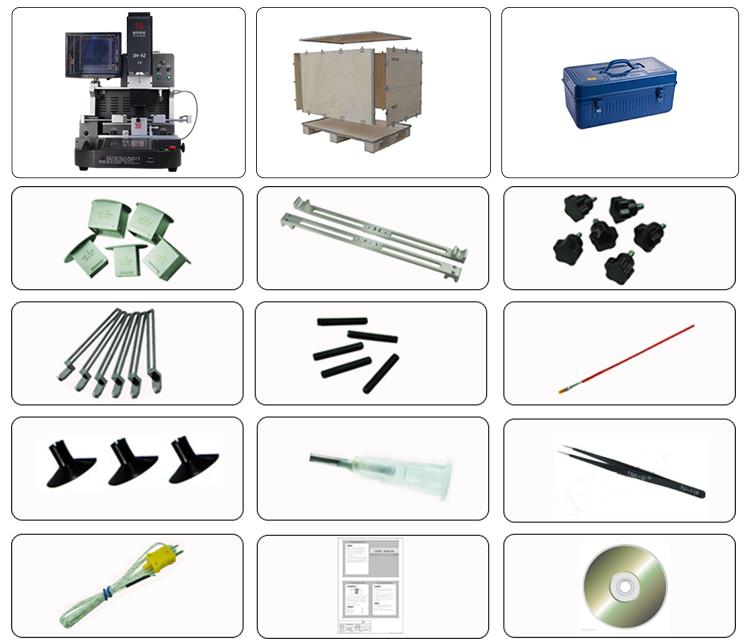

7.Packing & Shipment of CCD Camera Motherboard CPU Desoldering Heating Station

8.Shipment for Split Vision Automatic Motherboard CPU Desoldering

Heating Station

DHL/TNT/FEDEX. If you want other shipping term, please tell us. We will support you.

9. Operation guide for Optics Align Automatic Motherboard CPU Desoldering

Heating Station

10. Contact us for an instant reply and the best price.

Email: john@dh-kc.com

MOB/WhatsApp/Wechat: +86 15768114827

Click the link to add my WhatsApp:

https://api.whatsapp.com/send?phone=8615768114827

11. Related knowledge of Automatic BGA SMD Rework System Hot Air chips

China Domestic enterprises actively enter the chip field, special AI chip development speed

In 2018, it was a year in which the chip industry achieved many achievements. Both traditional chip manufacturers and start-ups have made many

attempts to improve the performance and computational density of chips. Up to now, Huawei, Baidu, Alibaba and other companies have joined the

chip track and are committed to producing more low-power, high-performance products. In the fierce market competition environment, companies

are stepping up the development of certain industry-specific chips such as FPGA chips and ASIC chips.

At present, with the rapid development of China's communications and electronic products manufacturing industries, the demand for chips in various

fields is also increasing, which has prompted chip manufacturers to conduct product development and production based on the actual needs of different

users. As a fully customized chip, ASIC chip has higher operating efficiency and lower cost per chip. Its practical application and development prospects

have also received much attention.

As the demand for edge computing continues to increase, the demand for ASIC chips has also increased significantly. Some researchers believe that by

2025, ASIC chips will account for more than 50% of the entire chip market. The reason why ASIC chips are favored is that the emerging deep learning

processor architecture is mostly based on graphics or Tensorflow.

Overall, the three specialized chips currently used by artificial intelligence are GPU, FPGA and ASIC. In terms of performance, area, power consumption,

etc., ASIC is superior to GPU and FPGA, so in the long run, ASIC represents the future of AI chip in both the cloud and the terminal. At present, the techn-

ology giants including Microsoft, Google, Intel, etc. have invested a lot of manpower and resources in the ASIC field, and hope to seize more development

opportunities in this field, and obtain more lucrative market returns.

Related products:

Hot air reflow soldering machine

Motherboard repairing machine

SMD micro components solution

LED SMT rework soldering machine

IC replacement machine

BGA chip reballing machine

BGA reball

Soldering desoldering equipment

IC chip removal machine

BGA rework machine

Hot air solder machine

SMD rework station

IC remover device